Read the FULL Article at Omron

https://automation.omron.com/en/us/solutions/success-stories/alpine-laser-controls-motion-remote-io

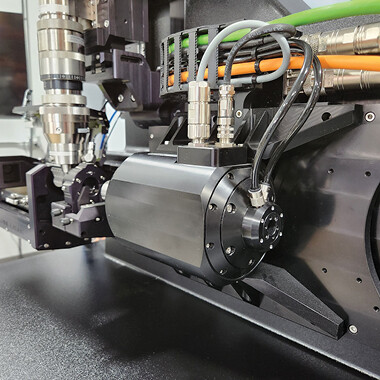

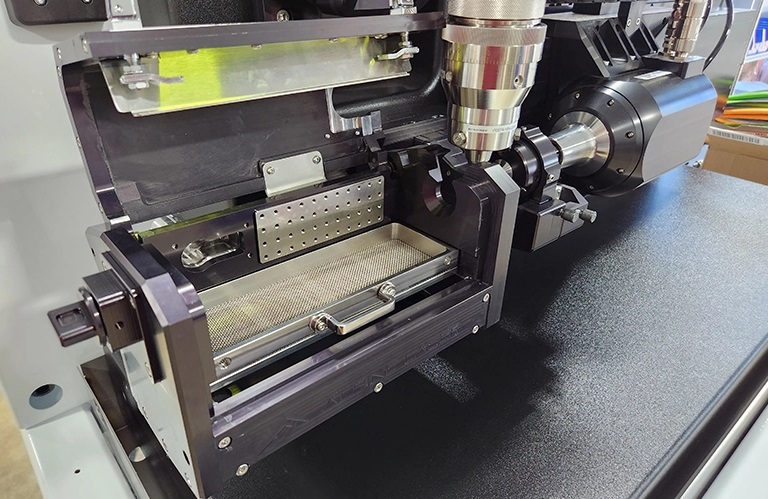

To address medical device manufacturers’ need for precisely cut stainless steel tubing, Bloomington, MN-based laser cutting manufacturer Alpine Laser conceived of a 100% purpose-driven solution that would improve throughput, reduce changeover time, ensure operator safety, and simplify maintenance.

Background

Stainless steel tubing is part of microcatheter shafts, structural heart valve frames, and other surgical materials that people’s lives depend on. Medical device manufacturers need tubing cut with excellent precision, so laser cutting workstations are essential for this industry.

From the beginning, Alpine Laser had a clear objective: to “hyper-focus” on the medical device industry’s business challenges and directly address concerns like constraints in manufacturing capacity within the laser cutting space and a lack of capacity among commercially available laser cutting equipment manufacturers.

From the beginning, Alpine Laser had a clear objective: to “hyper-focus” on the medical device industry’s business challenges and directly address concerns like constraints in manufacturing capacity within the laser cutting space and a lack of capacity among commercially available laser cutting equipment manufacturers.

Click here Read the FULL Article