How Alpine Laser created its medical tube cutting workstation

Head over to MedicalTubingandExtrusion to Read the FULL Article!

A partnership with Omron Automation Americas enabled Alpine Laser to create what it describes as an easy-to-support, modular machine for cutting stainless steel medical tubing.

Alpine Laser (Bloomington, Minnesota) recently launched its medical-tube-cutting Medicut Pro.

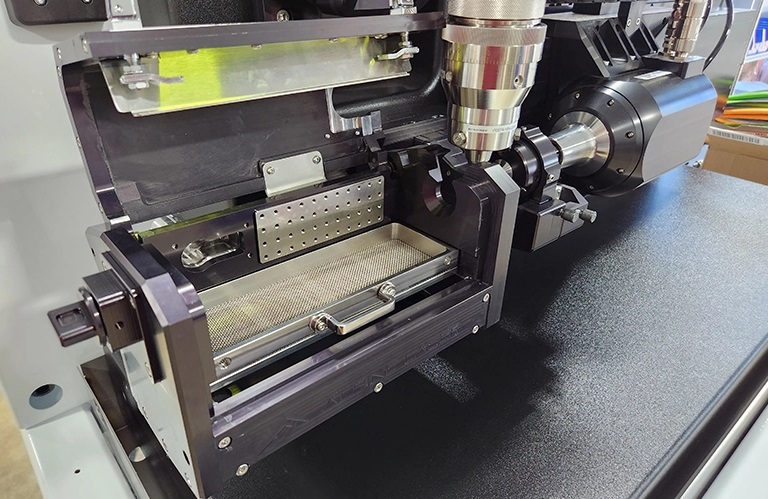

Alpine Laser describes the Medicut Pro as a purpose-driven and ultra-fast laser processing workstation for cutting stainless steel tubing. Such stainless-steel tubing plays an important role in microcatheter shafts, structural heart valve frames, stents and tubular components.

The Medicut Pro is faster (by a factor of two or more) than other systems on the market, according to Alpine Laser. Other positive features include a Precision Regrip Module with less than .0005 in. positional error, 3- to 5-minute tool changeover and rapid prototyping, a CAT III safety system, and the ability to service with off-the-shelf products that Alpine stocks.

Historically, medical device companies would adapt general-purpose machines to cut medical tubing. Alpine Laser officials thought they were well-positioned to improve on the situation and reduce the margin of error for such machines.

“We are a group of people with backgrounds in industrial machine design, high-volume medical manufacturing, and the medical device/therapy space. We deeply understand the needs of the customer and the market,” Joe Kempf, Alpine Laser’s founder and commercial leader, said in an article provided to Medical Tubing + Extrusion and Medical Design & Outsourcing by Omron Automation Americas.

Q&A: Omron and Alpine discussed their partnership in a Medical Design & Outsourcing webinar — watch the replay now.

Head over to MedicalTubingandExtrusion to Read the FULL Article!