Mediweld Pro Series Precision Laser Welding

Precision Laser Welding Workstation for Medical Device Manufacturing. Learn more about Configuration options below...

Designed for Medical Manufacturers

Mediweld PRO Series Laser Welding Workstations

Introducing, the Alpine Laser Mediweld PRO Series Laser Workstation. We've expanded our product portfolio building upon the sucess of our Laser Tube cutting workstations. The Mediweld PRO welding workstation combines High Precision motion, and Configurable standard options on a highly modular base platform.

Flexible Enough for Development, Robust enough for Production Environments

Our extensive experience as hands-on end-users and developers of ultra-precision medical manufacturing equipment has given us a deep understanding of the intricate requirements of these systems. With decades of experience and close collaborations with major Medical OEMs and startups, we have gained comprehensive knowledge covering a wide range of medical manufacturer's needs, from prototyping to high-volume production

Multi-Axis Configurations

Full CDRH & Safety Compliance

Fixturing & Tooling

Full Suite of Automated Software

Automated Part Loading

Designed for Ease of Use, Service and Scalability

Our design sets a new standard for ease of use, serviceability, and scalability. User-friendliness was a key focus during the design process, resulting in reduced learning curves and enhanced efficiency. Moreover, serviceability was given paramount importance, leading to the incorporation of easily accessible components and a streamlined maintenance process. Additionally, our design is highly scalable, facilitating smooth expansion and catering to businesses of all sizes.

Engineered for Flexibilty

Maintenence & Service

• Custom side-access sliding Electrical Cabinet allows back-to-back operation, without need to ever service or access rear side of the machine.

• Electronic and Controls systems designed to reduce complexity in terms of maintenance and replacement. Ability to change or replace discrete components without need for rewiring or incurring significant cost and downtime.

• Optional Secure Remote Access Gateway for full remote support and sofware upgades

Scalability

• Hardware and tooling designed for long-term, high-volume manufacturing

• Robust enough for high-volume manufacturing, flexible enough for prototyping

Mediweld Pro Standard Features

Below are a few of the features offered standard on all Medicut Pro Series Fiber Laser Workstations

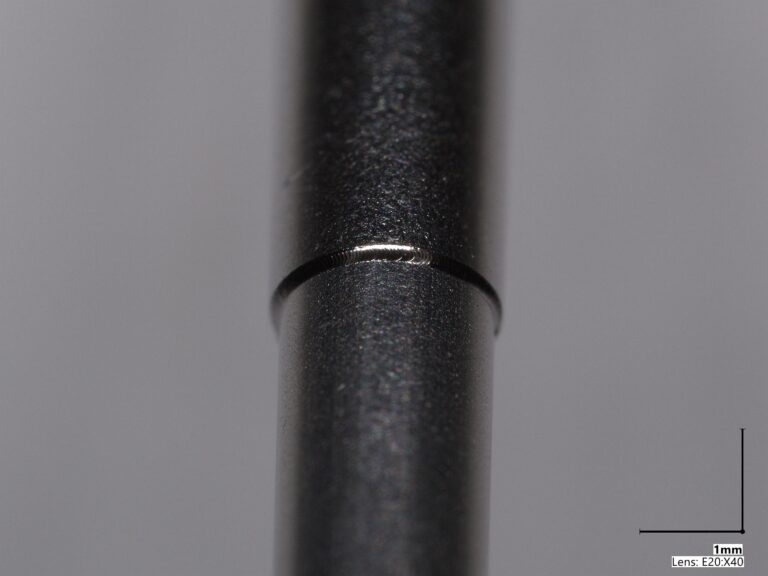

Fiber Laser Features

100-300W Laser Sources, Frequency up to 50kHz, Pulse Widths down to 15 microseconds. Pulse shapping and Simmer modes enable ultra-fine laser processing

Configurable Spot Size

Advanced Motion Control

• Control architecture allows for ultra-high speed synchronization

• Enables unparalleled cut speed, precision and accuracy

Custom Tooling

• Custom Tooling Design services available

• Pneumatic & vacuum tooling supported

• Precision 3-Jaw and/or Pneumatic ER options available

Ergonomic Design

4 Axis of Precision Motion

• Rotary A Axis available in 3Jaw or ER Collet

• 250mm Z Axis

Alpine HMI

Precision Process Gas Control

Mediweld Pro Optional Features

Below is a non-comprehensive list, featuring a few options that available for quoting by request